Project Description

| Product name | Bike Frame |

| Material | Titanium |

| Foldable | No |

| Size | Above 60cm |

| Use | Road Bicycles, Gravel bike for S&S Couplers |

| Weight | 1.65kg |

| parking | 1pcs/box,5pcs/bag |

| Surface Processing Mode | Matte |

| is_customized | yes |

| Type | Girder frame |

| Material | Carbon T900(Frame+Fork+Seat post) |

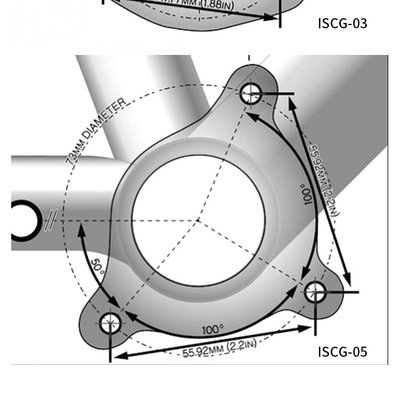

| Head tube size | 40*54mm Tapered |

| Feature | Light weight, corrosion resistance, appropriate strength

Corrosion and no rust, good riding feeling |

The frame material has evolved from the earliest chromium-molybdenum steel to aluminum alloy, and then the use of composite materials such as carbon fiber, as well as scandium alloys, magnesium alloys, titanium alloys, etc.

The chromium-molybdenum steel frame is an alloy steel made by adding one or more elements to carbon steel. The addition of two elements, molybdenum (Mo) and chromium (Cr), is called molybdenum-chromium alloy steel. The role of molybdenum: to increase the strength of steel and prevent temper brittleness. The role of chromium: corrosion resistance, rust resistance, prevent high temperature oxidation. Relatively rare. Before the 1990s, bicycle frames were mainly made of chromium molybdenum steel. It has good torsion and tensile properties, high temperature during welding will not affect the material, and the price is cheap. But it is heavy and easily oxidized. In recent years, new materials that overcome its shortcomings and take advantage of its advantages have emerged, and the chrome-molybdenum steel frame has once again attracted attention.

Steel is the longest frame material used on bicycles. The only drawback is that they are still heavier. Among the steels, chromium-molybdenum steel is the most common, which has high strength and is easy to pipe processing. Molybdenum can increase the strength of steel and prevent embrittlement; chromium can make steel corrosion-resistant, rust-resistant and prevent high-temperature oxidation.